Crafting Accessibility and Luxury

As home elevators become an increasingly popular feature in modern residences, the demand for precision, quality, and customization has driven innovation in manufacturing. A home elevator factory is where these sophisticated systems are brought to life, combining advanced engineering with meticulous craftsmanship. This article takes you on a tour through the various stages of the manufacturing process, showcasing how these essential home features are produced to meet the highest standards.

The Manufacturing Journey: From Concept to Creation

- Design and Engineering

- Conceptualization: The process begins in the design department, where engineers and designers collaborate to create elevator systems tailored to specific residential needs. Whether it’s a compact, space-saving unit for a small home or a more luxurious, spacious model for a high-end residence, every detail is considered during this phase.

- Customization Options: Factories provide extensive customization options, allowing homeowners to select from various cabin finishes, door types, control interfaces, and lighting features. This ensures that the elevator not only meets functional requirements but also complements the home’s aesthetic.

- Engineering Precision: Detailed engineering plans are developed to ensure the elevator meets all safety and performance standards. This includes load calculations, safety feature integration, and compatibility with existing home infrastructure.

- Material Selection and Procurement

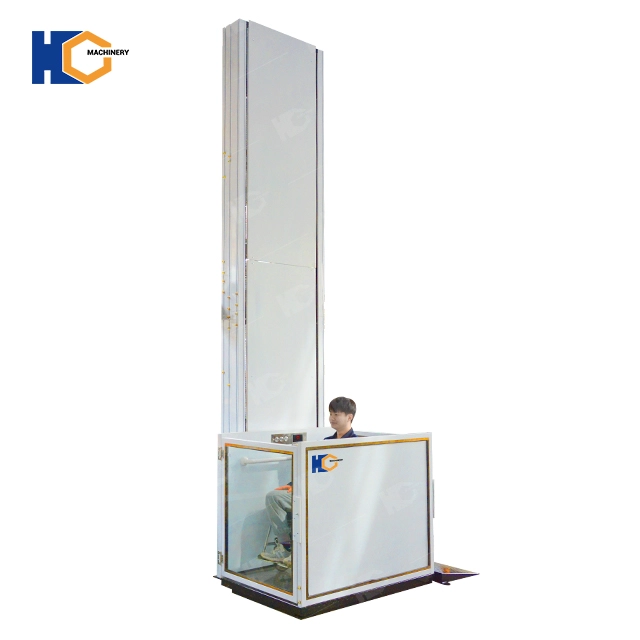

- High-Quality Materials: The choice of materials is crucial in the production of home elevators. Factories source premium materials like stainless steel, glass, aluminum, and high-grade composites to ensure durability, safety, and a sleek finish.

- Sustainable Sourcing: Many factories are increasingly focusing on sustainability, selecting eco-friendly materials and employing practices that reduce waste and minimize environmental impact.

- Precision Manufacturing

- Component Fabrication: In the factory, various components of the elevator—including the cabin, doors, rails, and control systems—are fabricated with precision. Advanced machinery is used to cut, shape, and assemble these components to meet exacting standards.

- Assembly Process: The assembly process combines automated systems with skilled craftsmanship. Each component is meticulously assembled to ensure the final product operates smoothly, safely, and quietly.

- Quality Control and Testing

- Rigorous Testing: Quality control is a critical stage in the manufacturing process. Each elevator undergoes rigorous testing to ensure it meets all operational and safety standards. This includes stress tests, safety feature checks, and simulations of various emergency scenarios.

- Safety Certifications: Factories ensure that their elevators comply with strict national and international safety standards. This involves thorough inspections and certification processes to guarantee that the elevators are safe for installation in homes worldwide.

- Final Customization and Finishing

- Personalized Touches: After the elevator passes all quality checks, it undergoes final customization. This stage involves adding the finishing touches, such as custom cabin interiors, special lighting, and advanced control panels, according to the client’s specifications.

- Final Inspection: Before leaving the factory, the elevator undergoes a final inspection to ensure every detail meets the highest standards of quality and craftsmanship.

- Packaging and Distribution

- Secure Packaging: The completed elevator is carefully packaged to protect it during transportation. Special attention is given to delicate components, which are securely packed to prevent damage.

- Global Shipping: Many factories have the capability to ship their elevators worldwide, ensuring that homeowners around the globe can benefit from these sophisticated systems. The elevators are typically shipped in parts and assembled on-site by trained technicians.

Innovation and Technology in Home Elevator Manufacturing

- Smart Technology Integration

- Advanced Features: Modern home elevators are often equipped with smart technology, including touchscreens, voice controls, and remote monitoring systems. Factories are at the forefront of integrating these features, providing homeowners with enhanced convenience and control.

- Energy Efficiency: Innovation also focuses on energy efficiency. Factories are developing elevators with energy-saving features like regenerative drives and LED lighting, reducing both the environmental impact and operating costs.

- Modular and Adaptable Design

- Flexible Systems: Factories offer modular elevator systems that can be easily adapted to different home layouts and architectural styles. This flexibility allows for easier installation and greater customization.

- Luxury Enhancements: For homeowners seeking a touch of luxury, factories offer high-end finishes and features, such as custom wood paneling, panoramic glass cabins, and integrated entertainment systems.

- Safety and Compliance

- Cutting-Edge Safety Features: Safety is a top priority in home elevator manufacturing. Factories are continually innovating to include the latest safety technologies, such as advanced braking systems, emergency power backups, and sophisticated sensor networks.

- Global Standards Compliance: To ensure their products can be installed in various regions, factories adhere to international safety standards and certifications. This compliance is crucial for ensuring the safety and reliability of elevators across different markets.

Conclusion: Crafting the Future of Home Mobility

A home elevator factory is where engineering precision, design innovation, and skilled craftsmanship converge to create products that elevate the standard of living. From the initial design phase to the final inspection, every step of the manufacturing process is meticulously managed to produce elevators that are not only functional but also a reflection of the homeowner’s style and needs. As demand for home elevators grows, these factories continue to push the boundaries of what is possible, ensuring that each elevator is a blend of safety, efficiency, and luxury.